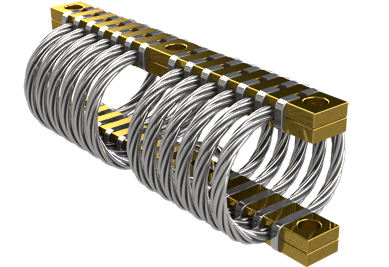

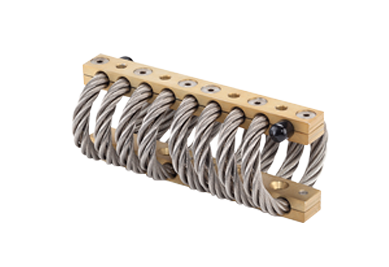

VMC Group C Series Helical Wire Rope Isolators are made up of helical stranded wire rope held with rugged metal retaining bars. This design provides excellent shock and vibration isolation for subcomponents inside of various types of equipment. All C Series Isolators offer specific response characteristics based on the diameter of the wire rope, the number of strands, the cable loop length and the number of loops per section. This performance is measureable and predictable.

Standard C Series Helical Wire Rope Isolators are made of stainless steel wire rope and corrosion resistant aluminum alloy retainer bars. Other materials including galvanized wire rope and stainless steel retainer bars are available. The isolators offer three plane, all-axis isolation that permits use in any attitude - vertically, horizontally and laterally. The large dynamic displacement attenuates heavy shocks, while the inherent damping provided by the sliding friction between the strands of the wire rope enable the C Series Isolators to minimize post-shock noise and lower resonant peaks.

The C Series Helical Wire Rope Isolators will function in any temperature from -400⁰F to +700⁰F. The isolators resist ozone, oil, grease, sand, salt spray and organic solvents - providing permanent solutions to any environmental demand. Once installed, the C Series need little or no maintenance and usually will outlast the protected equipment.

Features & Benefits

- Wide range of available sizes permits attachment to almost any machinery or enclosure regardless of weight

- Compact, low profile design and the ability to attenuate heavy shock loads with minimum deflection allows use where space is at a premium

- Three-plane, all-axis isolation means that the equipment is free to move in any direction - vertically, horizontally and laterally

- Custom winding, loop count and mounting features are available to meet specific requirements

- Special cable materials (galvanized steel and other stainless steel alloys), special bar materials (stainless steel, titanium finish platings) and special mounting configurations (inserts, thread types, clearance holes) to name just a few are available

Applications

- Power generation

- Truck, bus and recreational vehicles

- Shipping transports/containers

- Railroad

- Off-Highway construction equipment

- Offshore

- Commercial marine

- Mining

- Industrial machinery

DOWNLOADS

Spec Sheets

Submittal Drawings

RELATED SERVICES

The engineers we employ hold the highest industry-recognized credentials in structural analysis, elastomer development and system dynamics.

We are the first ISO accredited PCA ISO-17065, third-party certification body for special seismic certification of non-structural building components and their mounting configurations by the ICC’s International Accreditation Service.

We are the only ISO 17025:2005 Accredited Seismic Simulation Test Laboratory with a triaxial shake table owned and operated by California licensed Structural engineers.

Testing Services Update

DCL now offers Nuclear Qualification and Testing services.

In partnership with Greenberry Industrial, we now offer testing services that meet the requirements of ASME NQA-1.