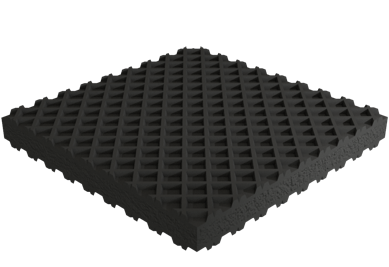

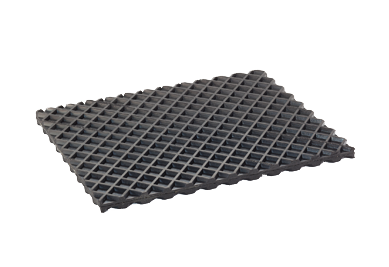

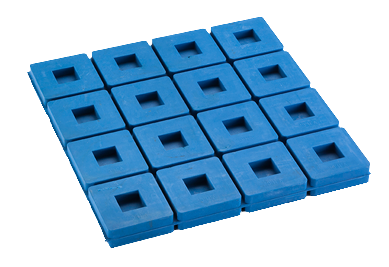

VMC Group VLM Isolators utilize oil-resistant neoprene elastomers to provide effective shock and vibration control for all types of power generation equipment. Built-in-leveling feature provides height adjustment to compensate for unequal isolator deflection or floor irregularities. Ribbed design of mounting base provides non-skid surface, eliminating the need for bolting to the floor. Cuts machine installation time from hours to minutes. Four sizes provide load capacities up to 12,000 pounds per isolator.

Features & Benefits

- Very wide static load range of 50 - 12,000 lbs. offers solutions for almost any production floor application

- Built-in leveling provides height adjustment for floor irregularities and/or unequal isolator deflection

- Ribbed isolator base provides a non-skid surface - eliminating the need to bolt machinery to the floor

- Corrosion-resistant coating on all metal surfaces provides extra durability

- Nominal frequency of 10 Hz provides structure-borne noise attenuation in even the most challenging installations

Applications

- Gensets

- Electrical transformers

- Switch gear equipment

- Motors

- Turbines

DOWNLOADS

Spec Sheets

Submittal Drawings

RELATED SERVICES

The engineers we employ hold the highest industry-recognized credentials in structural analysis, elastomer development and system dynamics.

We are the first ISO accredited PCA ISO-17065, third-party certification body for special seismic certification of non-structural building components and their mounting configurations by the ICC’s International Accreditation Service.

We are the only ISO 17025:2005 Accredited Seismic Simulation Test Laboratory with a triaxial shake table owned and operated by California licensed Structural engineers.

Testing Services Update

DCL now offers Nuclear Qualification and Testing services.

In partnership with Greenberry Industrial, we now offer testing services that meet the requirements of ASME NQA-1.